| View previous topic :: View next topic |

| Author |

Message |

cmkopp11

Joined: 26 Jan 2018

Posts: 19

Location: San Diego

|

Link Posted: Wed Mar 14, 2018 1:41 am Post subject: Question on cleaning in place Link Posted: Wed Mar 14, 2018 1:41 am Post subject: Question on cleaning in place |

|

|

Hi all,

So my system is all up and running. I used ss brewtech kettles that require a preclean and passivation step. I tested my system while doing this precleaning. I noticed that my MLT did was about 4 degrees off from my HLT after 20 minutes and my pv on the HLT PID was usually 3 degrees higher than my set point. Is this normal or should I try to run an auto tune or is there something else I'm missing?

The temperature of the water by floating thermeter (just what I have) was same as the rtd reading.

Edit: totally forgot the CIP question. In the brew day step by step the sparge goes through the HERMS to clean it. My question is how did you drain it? I made a god awful mess trying to drain it.

Thanks!

|

|

| Back to top |

|

|

kal

Forum Administrator

Joined: 12 Dec 2010

Posts: 11121

Location: Ottawa, Canada

Drinking: Pub Ale, Electric Creamsicle, Mild, Pliny the Younger, Belgian Dark Strong, Weizen, Russian Imperial Stout, Black Butte Porter

|

Link Posted: Wed Mar 14, 2018 4:38 am Post subject: Link Posted: Wed Mar 14, 2018 4:38 am Post subject: |

|

|

Hi!

Having a HLT to MLT temperature lag is a very common issue. Using parts that are different from the ones I recommend in our build instructions can cause this. To minimize the difference, make sure to:

- Calibrate both the MLT and HLT temp probes per the instructions here: http://www.theelectricbrewery.com/control-panel-setup

Unless both are calibrated with a known accurate thermometer at the mash temp, you donít know if what you are seeing is accurate.

- Make sure to set up the PIDs per the instructions here: http://www.theelectricbrewery.com/control-panel-setup

Use the thicker walled hoses I recommend here: http://www.theelectricbrewery.com/hoses

Thicker hoses will lose less heat. Try to minimize distances as well.

- Set your mill gap crush per the recommendations here (0.045 to 0.050"): http://www.theelectricbrewery.com/grain-mill

You want to mill looser for good flow, not tighter.

- Use the pumps I recommend here to ensure adequate flow: http://www.theelectricbrewery.com/pumps

- Run both pumps at 100% open when mashing. To get good flow without any channeling use the kettles I recommend here: http://www.theelectricbrewery.com/kettles-overview

For example, users have reported on our forum and by email how they were seeing a temperature differential between the MLT and HLT and were able to make it go away by swapped out their hoses and pumps for what's recommended in the build instructions. A quote from one of them:

"I had originally tested the HERMS with the thinner 1/2 ID silicon and had my pumps setup with the inline heads (long story). I was landing about 1-2 degrees cooler in the mash kettle. I swapped out the pump heads for the front inlet and swapped out the silicon with what you recommend and I now hit the same temp!" - Todd W.

Other things that are sometimes done differently that can cause a differential:

- Make sure the heating elements are wired correctly and being fed 240V and not 120V. Running heating elements at 120V will result in 1/4 the power you expect. You can check this by looking at the amp meter. A 4500W element will draw 18.8 amps while a 5500W element will draw 22.9 amps.

- Brewing in a very cold location may cause the MLT temp to drop slightly by the time it reaches the MLT temp probe.

This question gets asked a lot on the forum too. These threads may provide further hints:

http://www.theelectricbrewery.com/forum/viewtopic.php?t=25474

http://www.theelectricbrewery.com/forum/viewtopic.php?t=26722

http://www.theelectricbrewery.com/forum/viewtopic.php?t=30387

http://www.theelectricbrewery.com/forum/viewtopic.php?t=28283

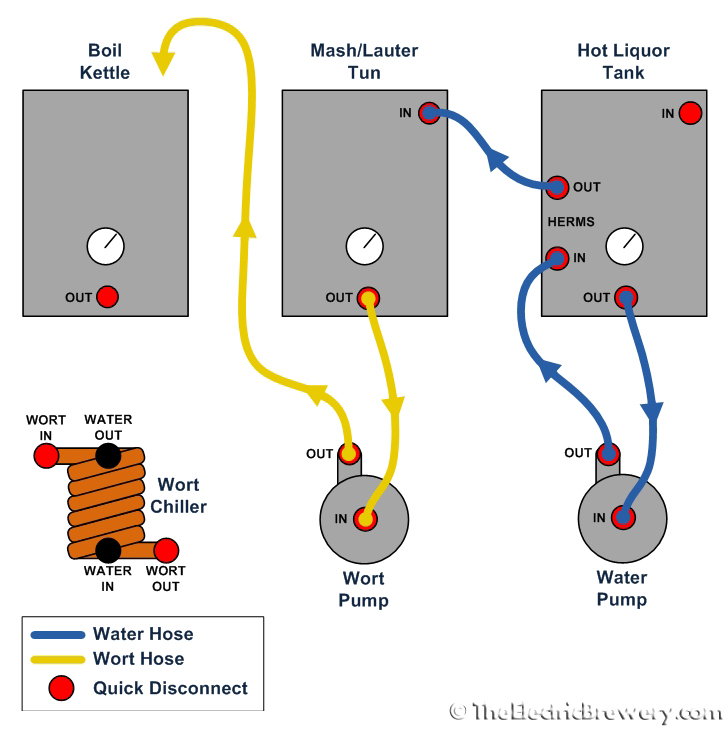

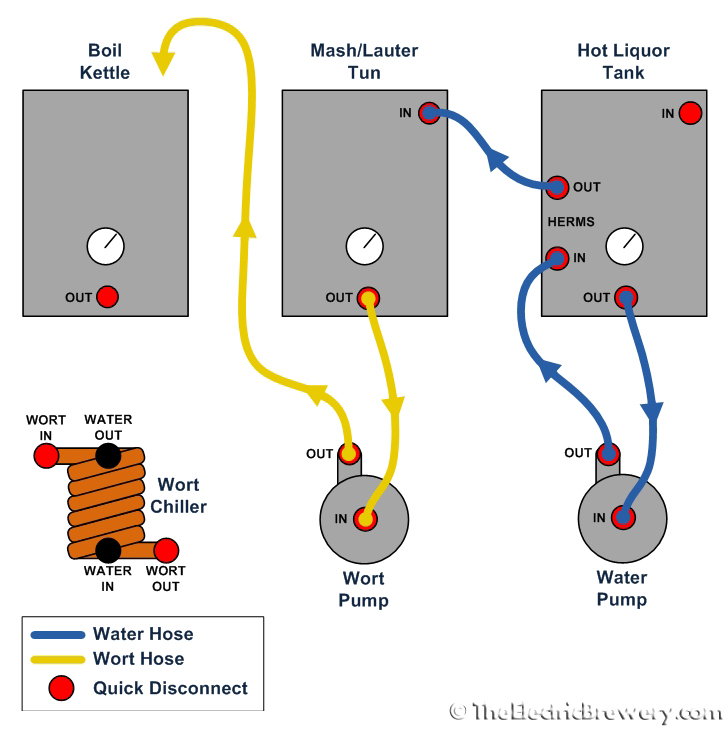

Re: Draining the HERMS coil. Refer to the SPARGE step of the BREW DAY STEP BY STEP instructions. This diagram:

When I'm done sparging I turn the water pump valve and MLT input valve off completely, disconnect the hose from the MLT input, disconnect the hose from the HLT output and put the end in a bowl or bucket on the floor. I then open the pump valve and all the water drains out. Nothing will be left in the HERMS coil.

Basically let gravity do the work and drain everything for you. Then a quick blow with the shopvac just to get rid of the last half ounce or so of standing water from the HERMS coil and pump. Hoses are hung to drip dry over the sink.

Good luck!

Kal

_________________

Our new shop with over 150 new products: shop.TheElectricBrewery.com

We ship worldwide and support our products and customers for life.

Purchasing through our affiliate links helps support our site at no extra cost to you. We thank you!

My basement/bar/brewery build 2.0

Last edited by kal on Wed Mar 14, 2018 7:12 pm; edited 1 time in total

|

|

| Back to top |

|

|

dp Brewing Company

Joined: 08 Jul 2013

Posts: 664

Location: Midwest

Drinking: Chocolate Taco, Raspberry Mango Cider, American X, Sandy Dunes

Working on: Nothing

|

Link Posted: Wed Mar 14, 2018 2:50 pm Post subject: Re: Question on cleaning in place Link Posted: Wed Mar 14, 2018 2:50 pm Post subject: Re: Question on cleaning in place |

|

|

| cmkopp11 wrote: |

Edit: totally forgot the CIP question. In the brew day step by step the sparge goes through the HERMS to clean it. My question is how did you drain it? I made a god awful mess trying to drain it.

Thanks! |

I leave the hose on the bottom coil input after I'm done sparging and then hook up a shopvac to the hose. It seems to do a good job sucking out all of the water.

_________________

Visit dp Brewing Company

Hangovers hurt....but good memories last forever!

|

|

| Back to top |

|

|

McGruber

Joined: 12 Aug 2014

Posts: 237

Location: Idaho

|

Link Posted: Thu Mar 15, 2018 3:17 pm Post subject: Re: Question on cleaning in place Link Posted: Thu Mar 15, 2018 3:17 pm Post subject: Re: Question on cleaning in place |

|

|

| cmkopp11 wrote: | | I noticed that my MLT did was about 4 degrees off from my HLT after 20 minutes and my pv on the HLT PID was usually 3 degrees higher than my set point. |

I have a fairly predictable 1'C offset, which I just live with and hasn't been a problem. I just set my HLT 1' higher.

| cmkopp11 wrote: | | In the brew day step by step the sparge goes through the HERMS to clean it. My question is how did you drain it? I made a god awful mess trying to drain it. |

I have a no-move hose set up, so when I'm done brewing and rinsing the lines, I attach a CO2 line to the end of one of my hoses and blow out all the lines into a bucket.

|

|

| Back to top |

|

|

cmkopp11

Joined: 26 Jan 2018

Posts: 19

Location: San Diego

|

Link Posted: Thu Mar 15, 2018 3:37 pm Post subject: Link Posted: Thu Mar 15, 2018 3:37 pm Post subject: |

|

|

|

Thanks everyone. The first brew was a success. I'm going to have to work on my cleaning process.

|

|

| Back to top |

|

|

|

|