| View previous topic :: View next topic |

| Author |

Message |

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Wed Feb 01, 2017 3:12 pm Post subject: Link Posted: Wed Feb 01, 2017 3:12 pm Post subject: |

|

|

Im using chugger stainless in-line pumps, bought when they first can out so they may have been improved since then but I will say they don't hold up over time to heat, I wouldn't subject these to any temp over 165f for long periods of time

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

dp Brewing Company

Joined: 08 Jul 2013

Posts: 664

Location: Midwest

Drinking: Chocolate Taco, Raspberry Mango Cider, American X, Sandy Dunes

Working on: Nothing

|

Link Posted: Wed Feb 01, 2017 3:25 pm Post subject: Link Posted: Wed Feb 01, 2017 3:25 pm Post subject: |

|

|

Interesting, I must have the improved ones. I've had mine for about 4 years. Never had any issues except for the time I didn't clean well enough and it was clogged shut. I had to take it apart and clean it, but I can't blame anyone but myself for that one.

_________________

Visit dp Brewing Company

Hangovers hurt....but good memories last forever!

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Wed Feb 01, 2017 3:26 pm Post subject: Link Posted: Wed Feb 01, 2017 3:26 pm Post subject: |

|

|

I whirl pool right after boiling and I think it erodes something or knocks the impeller out of balance

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

dp Brewing Company

Joined: 08 Jul 2013

Posts: 664

Location: Midwest

Drinking: Chocolate Taco, Raspberry Mango Cider, American X, Sandy Dunes

Working on: Nothing

|

Link Posted: Wed Feb 01, 2017 3:34 pm Post subject: Link Posted: Wed Feb 01, 2017 3:34 pm Post subject: |

|

|

| Ozarks Mountain Brew wrote: | | I whirl pool right after boiling and I think it erodes something or knocks the impeller out of balance |

I start recirculating with 20 minutes left (to sanitize the coil) and continue after time is up to whirlpool.

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Wed Feb 01, 2017 3:56 pm Post subject: Link Posted: Wed Feb 01, 2017 3:56 pm Post subject: |

|

|

I just ordered new impellers, although last time I took them apart I swear one fixed magnet hooked to the shaft wobbled, I report back

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

dp Brewing Company

Joined: 08 Jul 2013

Posts: 664

Location: Midwest

Drinking: Chocolate Taco, Raspberry Mango Cider, American X, Sandy Dunes

Working on: Nothing

|

Link Posted: Wed Feb 01, 2017 4:00 pm Post subject: Link Posted: Wed Feb 01, 2017 4:00 pm Post subject: |

|

|

I wonder if it has anything to do with the orientation of your pump heads. Mine are both horizontal and I see you have yours vertical. Wonder if air gets trapped before the impeller. Nothing concrete to base this on, just an observation.

_________________

Visit dp Brewing Company

Hangovers hurt....but good memories last forever!

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Wed Feb 01, 2017 4:15 pm Post subject: Link Posted: Wed Feb 01, 2017 4:15 pm Post subject: |

|

|

I had mine horizontal for years just changed mine last year, but had problems before that even

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

kal

Forum Administrator

Joined: 12 Dec 2010

Posts: 11121

Location: Ottawa, Canada

Drinking: Pub Ale, Electric Creamsicle, Mild, Pliny the Younger, Belgian Dark Strong, Weizen, Russian Imperial Stout, Black Butte Porter

|

Link Posted: Wed Feb 01, 2017 4:27 pm Post subject: Link Posted: Wed Feb 01, 2017 4:27 pm Post subject: |

|

|

Not sure about damages or other issues, but look at the pics that Ozarks Mountain Brew posted, he'll definitely having priming issues because:

- The heads are not 3/4" center inlet which aid in priming/head flooding.

- The fact that he's feeding from below and there's a height difference between the hose and the pump (a vertical climb to the head). Always try and minimize this distance.

- The vertical distance between kettle outputs and the pump heads is not very large (the force will be low once the water or wort reaches the pump). Always try and maximize this distance.

Bleeder valves would definitely help which I believe he has. (Not required if you do what I recommend above - I don't use any and never have pump priming issues).

Kal

_________________

Our new shop with over 150 new products: shop.TheElectricBrewery.com

We ship worldwide and support our products and customers for life.

Purchasing through our affiliate links helps support our site at no extra cost to you. We thank you!

My basement/bar/brewery build 2.0

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Wed Feb 01, 2017 4:47 pm Post subject: Link Posted: Wed Feb 01, 2017 4:47 pm Post subject: |

|

|

I agree with Kal but just to be clear these issues are not related to this latest design, Ive had issues for years but always managed to make them work by fiddling on brew day, bleeder valves would help the vapor locks defiantly and you can use the out port for that with the left pump but the heat related issues are a big issue

center inlet pumps may be the answer

|

|

| Back to top |

|

|

kal

Forum Administrator

Joined: 12 Dec 2010

Posts: 11121

Location: Ottawa, Canada

Drinking: Pub Ale, Electric Creamsicle, Mild, Pliny the Younger, Belgian Dark Strong, Weizen, Russian Imperial Stout, Black Butte Porter

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Wed Feb 01, 2017 6:32 pm Post subject: Link Posted: Wed Feb 01, 2017 6:32 pm Post subject: |

|

|

I cant see how this design will work with center inlet pump heads, the ball valve handle would hit, maybe Ill look at a redesign

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Fri Feb 03, 2017 4:34 pm Post subject: Link Posted: Fri Feb 03, 2017 4:34 pm Post subject: |

|

|

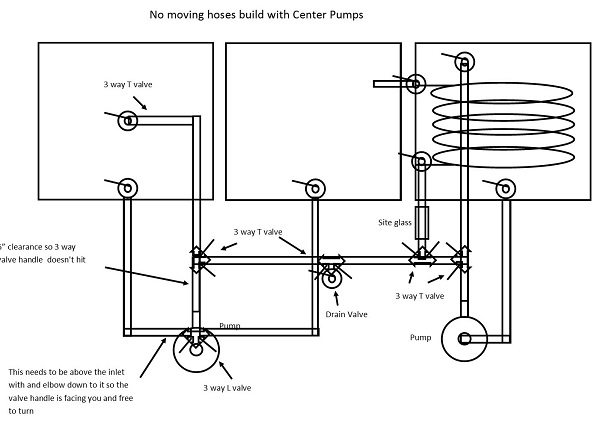

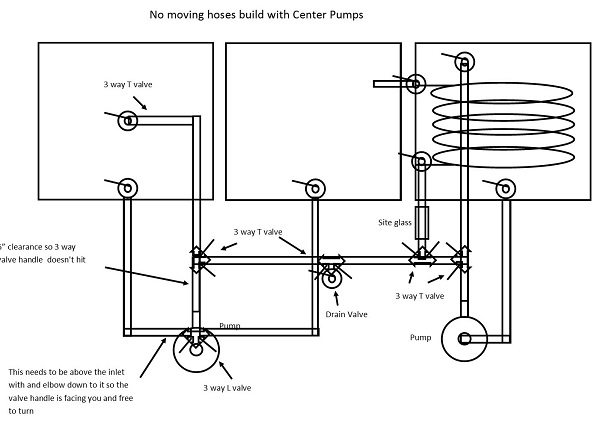

this is my latest drawing with the center pumps, and the added connection to using the HLT as a chiller, totally optional, the only issue might be how the 3 way valve on the left pump is set up, a trial and error in that set up should be done, a note that the taller tables that kal recommends will allow for the correct hose size to keep the flow the same

there needs to be a definite clearance for the 3 way ball valve handles to spin all the way around so unfortunately pipe on top of the pump is necessary, take a look

| Description: |

|

| Filesize: |

73.62 KB |

| Viewed: |

22450 Time(s) |

|

|

|

| Back to top |

|

|

Firebrewmedic43

Joined: 23 Dec 2014

Posts: 104

Location: Tennessee

Drinking: barrel-aged Foreign Export Stout

Working on: Helles

|

Link Posted: Wed Feb 08, 2017 5:05 am Post subject: Link Posted: Wed Feb 08, 2017 5:05 am Post subject: |

|

|

|

My pumps are oriented vertically as well. An earlier post in this thread referenced an article in BYO on Pumps. Since I had the march pumps prior to finding this site I chose not to use the center inline pumps. The relief valve is invaluable. I have had to use them a couple of times and they work like a charm to get fluid moving. I just completed my second and third batch (yes a double brew day). Im still getting use to turning the valves at the right time but Im really liking this Electric system. Wish I had found it years ago. Thanks Kal...This forum has been a huge help as well. Brewed a saison using the Belle Saison yeast from Lallemand and Scotch using the Scottish ale yeast (1728) from Wyeast.

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Wed Feb 08, 2017 11:07 pm Post subject: Link Posted: Wed Feb 08, 2017 11:07 pm Post subject: |

|

|

ok this is a decent pick of my kettles, Im revamping my control panel at the moment

| Description: |

|

| Filesize: |

122.21 KB |

| Viewed: |

22418 Time(s) |

|

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

dp Brewing Company

Joined: 08 Jul 2013

Posts: 664

Location: Midwest

Drinking: Chocolate Taco, Raspberry Mango Cider, American X, Sandy Dunes

Working on: Nothing

|

Link Posted: Thu Feb 09, 2017 1:27 pm Post subject: Link Posted: Thu Feb 09, 2017 1:27 pm Post subject: |

|

|

What size kettles do you use Ozarks?

_________________

Visit dp Brewing Company

Hangovers hurt....but good memories last forever!

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Thu Feb 09, 2017 1:35 pm Post subject: Link Posted: Thu Feb 09, 2017 1:35 pm Post subject: |

|

|

I have 2-20s and 1-25 pot but concord brand

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Sun Feb 12, 2017 1:01 am Post subject: Link Posted: Sun Feb 12, 2017 1:01 am Post subject: |

|

|

update on my pumps, replaced my impellers and wallah absolutely perfect now, not even a squeak, no disengaging at high heat, no priming vapor locks, better than new

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Sat Mar 04, 2017 9:28 pm Post subject: Link Posted: Sat Mar 04, 2017 9:28 pm Post subject: |

|

|

| laureate wrote: | Thanks to Firebrewmedic43 and Ozarks for the pics - great setups. Just wondering if there are any lessons learned or things you would have done differently? I'm considering a similar setup but with actuated valves.

Also Ozarks, any chance you could take a pic of the rest of your rig?

Thanks again and nice work! |

well after brewing with this a few times, the only issues I would say are cleaning an enclosed system, water, wort or soap are always left somewhere and no matter how clean you get it you still have to flush it out before brewing the next time, the only real way to clean is to take the hoses off and spray the valves out with a spray nozzle and let it air dry otherwise you get a sour smell out of the first rinse the next brew day

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

perogi

Joined: 12 Feb 2012

Posts: 850

Location: NH

Drinking: Perogi Pale, NEIPA, Nutter's Crossing Nut Brown Ale, Edmund Fitzgerald Porter Clone

Working on: Max's Maibock

|

Link Posted: Sat Dec 30, 2017 11:55 pm Post subject: Link Posted: Sat Dec 30, 2017 11:55 pm Post subject: |

|

|

| ParadiseBrew wrote: | | I have the same setup as well. When i was building my system i contacted Holter on how he liked the wood base for his shelving system. He explained that it's kinda a pain and wish he had gone with something else.... for my build i used a thick stall mat you can get at tractor supply. one big sheet cuts in half for two shelves. i have been brewing on my electric system for a year now and love the simple cleanup of the stall mat. looks new and easy to clean. |

Hi ParadiseBrew - is this the mat you are referring to? https://www.tractorsupply.com/tsc/product/4-ft-x-6-ft-x-3-4-in-thick-rubber-stall-mat

Thanks!

|

|

| Back to top |

|

|

ParadiseBrew

Joined: 09 Dec 2014

Posts: 83

Location: paradise, ca

|

Link Posted: Tue Jan 02, 2018 9:04 pm Post subject: Link Posted: Tue Jan 02, 2018 9:04 pm Post subject: |

|

|

| perogi wrote: | | ParadiseBrew wrote: | | I have the same setup as well. When i was building my system i contacted Holter on how he liked the wood base for his shelving system. He explained that it's kinda a pain and wish he had gone with something else.... for my build i used a thick stall mat you can get at tractor supply. one big sheet cuts in half for two shelves. i have been brewing on my electric system for a year now and love the simple cleanup of the stall mat. looks new and easy to clean. |

Hi ParadiseBrew - is this the mat you are referring to? https://www.tractorsupply.com/tsc/product/4-ft-x-6-ft-x-3-4-in-thick-rubber-stall-mat

Thanks! |

Yes this is the one, you can cut one in half to use on two shelves. I have had the same ones down for two years now with no issues, they are one the best investments to my brew structure. kettles go right on top without issues, no stains and worries about water/wort dripping.

Let us know how they work out!!

|

|

| Back to top |

|

|

|

|