|

|

|

|

|

|

|

| View previous topic :: View next topic |

| Author |

Message |

USMChueston0311

Joined: 20 Aug 2018

Posts: 36

|

Link Posted: Sun Oct 07, 2018 6:06 am Post subject: Wort ending up in HLT? Link Posted: Sun Oct 07, 2018 6:06 am Post subject: Wort ending up in HLT? |

|

|

Brewed today, first day on new 3 kettle EHERMS system. setup like blichmanns pilot system with 2 3 way ball valves on the pumps. With the HLT pump and valve to the left, for whirpool in HLT, the right side of valve and the line that would send sparge/strike water to MLT was full of wort, I noticed inside the HLT was brown, obviously wort had entered. Im guessing it went through the ball valve...

Anyone else have this happen, and any ideas on how to stop this from happening? Didnt like to have to PBW the HLT as well as both other kettles.

|

|

| Back to top |

|

|

USMChueston0311

Joined: 20 Aug 2018

Posts: 36

|

Link Posted: Sun Oct 07, 2018 6:08 am Post subject: Link Posted: Sun Oct 07, 2018 6:08 am Post subject: |

|

|

|

Im assuming it somehow got into the left side of the valve that sent the water into whirlpool for temp stratification. No other way.

|

|

| Back to top |

|

|

kal

Forum Administrator

Joined: 12 Dec 2010

Posts: 11120

Location: Ottawa, Canada

Drinking: Pub Ale, Electric Creamsicle, Mild, Pliny the Younger, Belgian Dark Strong, Weizen, Russian Imperial Stout, Black Butte Porter

|

|

| Back to top |

|

|

USMChueston0311

Joined: 20 Aug 2018

Posts: 36

|

Link Posted: Sun Oct 07, 2018 5:43 pm Post subject: Link Posted: Sun Oct 07, 2018 5:43 pm Post subject: |

|

|

| kal wrote: | Do you have flow diagrams that show how everything is set up including these 3 way ball valves and how you used? Similar to my BREW DAY STEP BY STEP diagrams?: http://www.theelectricbrewery.com/brew-day-step-by-step

Otherwise it's going to be hard to understand how it's set up and what you did as your setup doesn't follow the design outlined on this website (the design that I and most people reading this use).

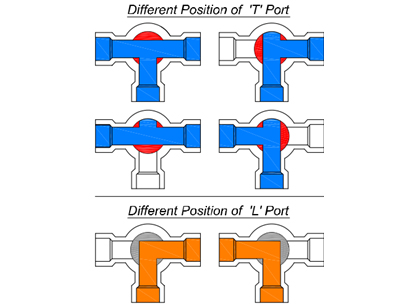

Now that said, you're always going to get some mixing between sides simply due to contact. There are also different types of 3-way ball valves (L vs T) that do different things:

If using a 3-way valve you shouldn't be using it for both water and wort as some contact between the two will happen no matter what.

Kal |

here is a diagram of my hoses. for whatever reason this forum software still will not let me upload any real pictures. Im thinking the wort came out through the top side of the TEE on herms input (the hose on water pump, right side of ball valve, and when i switched over to send sparge water it let some in. My ball valves, when the handle is at 12 o clock, both left and ride side is open, same at 6 o clock, when at left the 9 oclock side is open, and 3 oclock is closed, and vice versa. Just have never read about this happening, did a search. Wasnt planning on having to PBW and clean the HLT, or herms coil, but I had to as clean water didnt pass through at the end of sparge cleaning it and leaving the HLT only exposed to water.

Im guessing the Ball valves I have are the one on bottom of your picture. Tried to upload pics of them, but failed.

| Description: |

|

| Filesize: |

47.55 KB |

| Viewed: |

14773 Time(s) |

|

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Sun Oct 07, 2018 7:34 pm Post subject: Link Posted: Sun Oct 07, 2018 7:34 pm Post subject: |

|

|

I have a no moving hose set up and I have 4 - 3 way valves and I've found that sometimes they leak the other direction and also get wort trapped inside so I do a full fly sparge cleanout right before I brew, and always get colored water out

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Sun Oct 07, 2018 7:41 pm Post subject: Link Posted: Sun Oct 07, 2018 7:41 pm Post subject: |

|

|

I forgot to mention mostly the pumps too

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

kal

Forum Administrator

Joined: 12 Dec 2010

Posts: 11120

Location: Ottawa, Canada

Drinking: Pub Ale, Electric Creamsicle, Mild, Pliny the Younger, Belgian Dark Strong, Weizen, Russian Imperial Stout, Black Butte Porter

|

Link Posted: Sun Oct 07, 2018 7:56 pm Post subject: Link Posted: Sun Oct 07, 2018 7:56 pm Post subject: |

|

|

| Ozarks Mountain Brew wrote: | | I have a no moving hose set up and I have 4 - 3 way valves and I've found that sometimes they leak the other direction and also get wort trapped inside so I do a full fly sparge cleanout right before I brew, and always get colored water out |

Maybe I'm missing it, but I've never understood the benefits of a no moving hose setup because the reasons you've stated here. To me it sounds like the amount of extra time spent cleaning would be more than the few seconds it takes to move hoses, no? Plus it can be more confusing to use when you have 3-way valves.

... At least it was when I designed my brew day process and wrote down the steps and looked at 3-way without hose moves vs 2-way with hose moves. If your process is different you may have different results however.

Kal

_________________

Our new shop with over 150 new products: shop.TheElectricBrewery.com

We ship worldwide and support our products and customers for life.

Purchasing through our affiliate links helps support our site at no extra cost to you. We thank you!

My basement/bar/brewery build 2.0

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Sun Oct 07, 2018 8:04 pm Post subject: Link Posted: Sun Oct 07, 2018 8:04 pm Post subject: |

|

|

oh yes it can be confusing , I had to put directional washers on the valves and sometimes I still get confused or wrong plus I do a thorough water cleanout at the end of my brew day and still get gunk out the next brew day so it's just a routine now to do a thorough pbw then star-sans right before brewing, I don't use full water but all the pipes and valves get cleaned and itís an extra 30 minutes or longer on brew day

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

USMChueston0311

Joined: 20 Aug 2018

Posts: 36

|

Link Posted: Sun Oct 07, 2018 8:09 pm Post subject: Link Posted: Sun Oct 07, 2018 8:09 pm Post subject: |

|

|

I was totally new to electric brewing, and still am lol, only one brew under my belt so far with new system. But I got a really good deal through Blichmann, and decided to use their hose configuration. i still have to move hoses to whirpool, and divert through chiller. I dont like the leaking aspect when I move hoses, however if you put a towel under and move strategically this is really limited.

I did jump a step as i was excited, I went straight to sparge after mash, instead of raising to 168, and then heating the sparge water. So when I switched the valves I could have allowed the wort into the HLT. Not a super big deal, but I would rather not have to PBW the HLT and HERMS coil. It was a long day, at about 10 hours total from start to finish. I will do it a bit differently next time, and sanitize and soak all fermenter parts inside my conical the day before, and mill my grains the day before, as well as getting all boil additions seperated and labeled. That way as soon as I reach temps I can start brewing.

Kal I use 2 riptide pumps, and in your brew day instructions it says you run your pumps during mash circulation at full speed... When i run riptides at full speed it moves the water/wort VERY fast, is this not an issue with channeling ETC in the MLT? I think thats what slowed my heatup time after i added grains, because I limited the flow of the wort pump because I was worried about this, so it didnt heat back up to strike temp as fast as I would have liked. Will it be an issue with channeling oxidation ETC to run at full speed?

|

|

| Back to top |

|

|

USMChueston0311

Joined: 20 Aug 2018

Posts: 36

|

Link Posted: Sun Oct 07, 2018 8:11 pm Post subject: Link Posted: Sun Oct 07, 2018 8:11 pm Post subject: |

|

|

| kal wrote: | | Ozarks Mountain Brew wrote: | | I have a no moving hose set up and I have 4 - 3 way valves and I've found that sometimes they leak the other direction and also get wort trapped inside so I do a full fly sparge cleanout right before I brew, and always get colored water out |

Maybe I'm missing it, but I've never understood the benefits of a no moving hose setup because the reasons you've stated here. To me it sounds like the amount of extra time spent cleaning would be more than the few seconds it takes to move hoses, no? Plus it can be more confusing to use when you have 3-way valves.

... At least it was when I designed my brew day process and wrote down the steps and looked at 3-way without hose moves vs 2-way with hose moves. If your process is different you may have different results however.

Kal |

Here is a link to another thread on HBT that has the pictures of my issue in them. Everytime i tried to upload them here in this thread, it would say file empty or something to that affect.

https://www.homebrewtalk.com/forum/threads/wort-mixed-into-hlt.656643/

Please forgive me if Im breaking a rule etc by adding an external link, I just want to be able to show you exactly what Im talking about.

|

|

| Back to top |

|

|

Ozarks Mountain Brew

Joined: 22 May 2013

Posts: 737

Location: The Ozark Mountains of Missouri

|

Link Posted: Sun Oct 07, 2018 8:12 pm Post subject: Link Posted: Sun Oct 07, 2018 8:12 pm Post subject: |

|

|

sorry this is very dirty we just had a huge rain storm

| Description: |

|

| Filesize: |

207.14 KB |

| Viewed: |

14734 Time(s) |

![WP_20180810_12_55_30_Pro[1].jpg](files/wp_20180810_12_55_30_pro1_102.jpg)

|

_________________

"Imagination is more important than knowledge. Knowledge is limited. Imagination encircles the world."

|

|

| Back to top |

|

|

kal

Forum Administrator

Joined: 12 Dec 2010

Posts: 11120

Location: Ottawa, Canada

Drinking: Pub Ale, Electric Creamsicle, Mild, Pliny the Younger, Belgian Dark Strong, Weizen, Russian Imperial Stout, Black Butte Porter

|

Link Posted: Sun Oct 07, 2018 8:16 pm Post subject: Link Posted: Sun Oct 07, 2018 8:16 pm Post subject: |

|

|

| USMChueston0311 wrote: | | i still have to move hoses to whirpool, and divert through chiller. I dont like the leaking aspect when I move hoses, however if you put a towel under and move strategically this is really limited. |

I close the associated valve before I disconnect and then use a small bowl to catch the few drips that are unavoidable. I find it works well.

| USMChueston0311 wrote: | | Kal I use 2 riptide pumps, and in your brew day instructions it says you run your pumps during mash circulation at full speed... When i run riptides at full speed it moves the water/wort VERY fast, is this not an issue with channeling ETC in the MLT? |

Not for me, on my setup.

| Quote: | | Will it be an issue with channeling oxidation ETC to run at full speed? |

Regarding channeling: On my setup as designed, no. If yours is different (different configuration, different false bottom/kettle) then I don't know.

Oxidation isn't any issue.

Kal

_________________

Our new shop with over 150 new products: shop.TheElectricBrewery.com

We ship worldwide and support our products and customers for life.

Purchasing through our affiliate links helps support our site at no extra cost to you. We thank you!

My basement/bar/brewery build 2.0

|

|

| Back to top |

|

|

USMChueston0311

Joined: 20 Aug 2018

Posts: 36

|

Link Posted: Sun Oct 07, 2018 8:29 pm Post subject: Link Posted: Sun Oct 07, 2018 8:29 pm Post subject: |

|

|

|

I have basically the same setup as yours, except two different pumps. I use the blichmann false bottom in g2 20 gallon kettles. Different HERMS coil, and I use an auto sparge, but the hose comes off of it as does yours, except mine is not as long. I will have to go back through your brewday walk through, and see if you have any videos of mashing while recirculating, to try and see how high the flow rate is up to 7 GPM. Im not sure what the pumps you use are pulling, but it comes out pretty hard.I direct it around the side of the kettle.

|

|

| Back to top |

|

|

kal

Forum Administrator

Joined: 12 Dec 2010

Posts: 11120

Location: Ottawa, Canada

Drinking: Pub Ale, Electric Creamsicle, Mild, Pliny the Younger, Belgian Dark Strong, Weizen, Russian Imperial Stout, Black Butte Porter

|

|

| Back to top |

|

|

USMChueston0311

Joined: 20 Aug 2018

Posts: 36

|

Link Posted: Sun Oct 07, 2018 9:03 pm Post subject: Link Posted: Sun Oct 07, 2018 9:03 pm Post subject: |

|

|

Yup, just re read and watched the mashing, and sparging videos again. Thank you, again, for all you have done to revolutionize the brewing realm, and always being there when your help is needed. Truly one of a kind.

-Steve

|

|

| Back to top |

|

|

kal

Forum Administrator

Joined: 12 Dec 2010

Posts: 11120

Location: Ottawa, Canada

Drinking: Pub Ale, Electric Creamsicle, Mild, Pliny the Younger, Belgian Dark Strong, Weizen, Russian Imperial Stout, Black Butte Porter

|

|

| Back to top |

|

|

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

Forum powered by phpBB © phpBB Group

|

|

![WP_20180810_12_55_30_Pro[1].jpg](files/wp_20180810_12_55_30_pro1_102.jpg)